Rhopoint Optimap3 PSD

Why Optimap3 PSD?

-

Full-field surface mapping in under 10 seconds — cover a 65 x 54 mm area in one measurement.

-

Unmatched resolution — lateral resolution < 37 µm reveals surface defects invisible to the naked eye.

-

Dual-mode operation — supports both reflective (mirror/bright) and dull surfaces using different fringe frequencies.

-

Non-contact measurement — safe for wet coatings; uniquely captures “orange peel” on freshly applied paint.

-

On-board, intuitive interface — 10.1″ capacitive touch screen, cross-section analysis, and instant 3D visualization.

-

Portable and robust — battery-powered, harness-mount points, rugged base options, and factory/Lab or on-site use.

-

Industry-ready outputs — Provides data in SI units or industry scales (e.g., “orange peel” units, waviness, DOI).

Key Applications & Industries

Optimap3 PSD excels in sectors where surface appearance and finish matter critically:

-

Automotive — Inspect exterior panels, clearcoats, E-coats, vinyl wrap, chrome parts.

-

Plastics & Composites — Analyze molded or curved components for texture, primer or topcoat defects.

-

Furniture & Metal Finishing — Evaluate lacquered, polished or curved surfaces for waviness or inclusions.

-

Paints & Coatings R&D — Measure wet paint finish, study defect formation (blistering, waterstains, sagging).

-

Consumer Electronics / High-End Surfaces — For device covers, panels, and premium finishes that demand uniformity.

How It Works — Measurement Principle

-

Phase-Measurement Deflectometry (PMD):

Fringe (striped) patterns are projected from an internal screen. The patterns shift in X and Y (phase stepping). -

Reflection & Capture:

The surface reflects these patterns. Because of surface texture or defects, the reflected patterns are distorted. An internal dual-focus camera captures these distortions. -

Topographic Mapping:

Built-in software reconstructs surface slope maps from the phase data. From there, it computes curvature (or altitude) maps showing waviness, orange peel, and more. -

Dual Surface Modes:

-

Reflective mode (high-frequency fringes) for glossy or shiny surfaces.

-

Dull mode (low-frequency fringes) for matte or low-reflectance surfaces.

-

-

Analysis Tools:

-

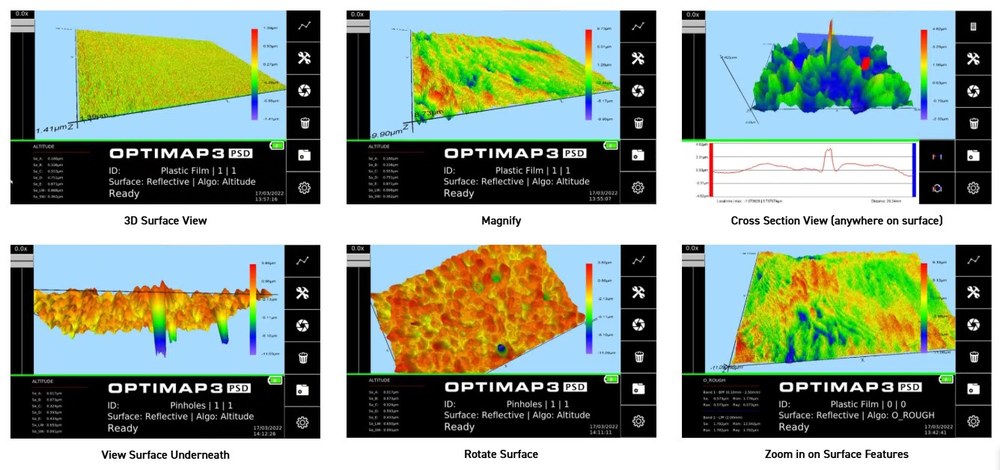

On-screen cross-sections: touch any point on the 3D map to generate profile plots over X / Y axes.

-

Magnification slider lets you zoom in on features.

-

Measurable Parameters & Defects

Optimap3 PSD can detect and quantify:

-

Orange peel (surface “skin” texture)

-

Waviness (low-frequency surface undulations)

-

Distinctness of Image (DOI) — how clearly a reflection appears

-

Overspray — unintended surface material

-

Inclusions — foreign particles embedded in the coating or substrate

-

Blistering / Bubbling

-

Sagging / runs

-

Water stains / spots

Key Benefits

-

Highly Representative Results: One fast full-area measurement gives you objective, quantifiable data that’s more meaningful than subjective visual inspections.

-

Defect Detection & Characterization: Identify, map and size defects, waviness or texture variations with 3D mapping.

-

Portable & Versatile: Battery powered, lightweight—even usable in the field or on production lines.

-

User-Friendly: Touch-screen interface, intuitive operations, fast training.

-

Industry Correlation: Measurement parameters correlate with visual appearance standards (e.g., automotive “orange peel” scales) and interferometry.

-

Robust Data Handling: Store data locally, analyze offline, export maps or CSV, integrate with SPC systems.

Ideal For

-

Quality Control Teams in automotive, coatings and plastics manufacturing

-

R&D Laboratories developing new finishes or paint formulations

-

Process Engineers optimizing finishing lines to reduce defects and material waste

-

Manufacturing Maintenance for periodic inspection of surface appearance on production parts

References

| Reference | Description | Buy |

|---|---|---|

| RHO-OPTIMAP | OPTIMAP deflectometer, maps and measueres surface quality | Request quotation |

| RHO-OPTIMAPPSD | OPTIMAP deflectometer, maps and measueres surface quality | Request quotation |